No products in the cart.

Beyond our primary product lines, we offer an expanded selection of materials to support a wide range of research and production needs. The following list represents commonly requested options. If you are looking for a material not included here, please contact us to discuss your requirements.

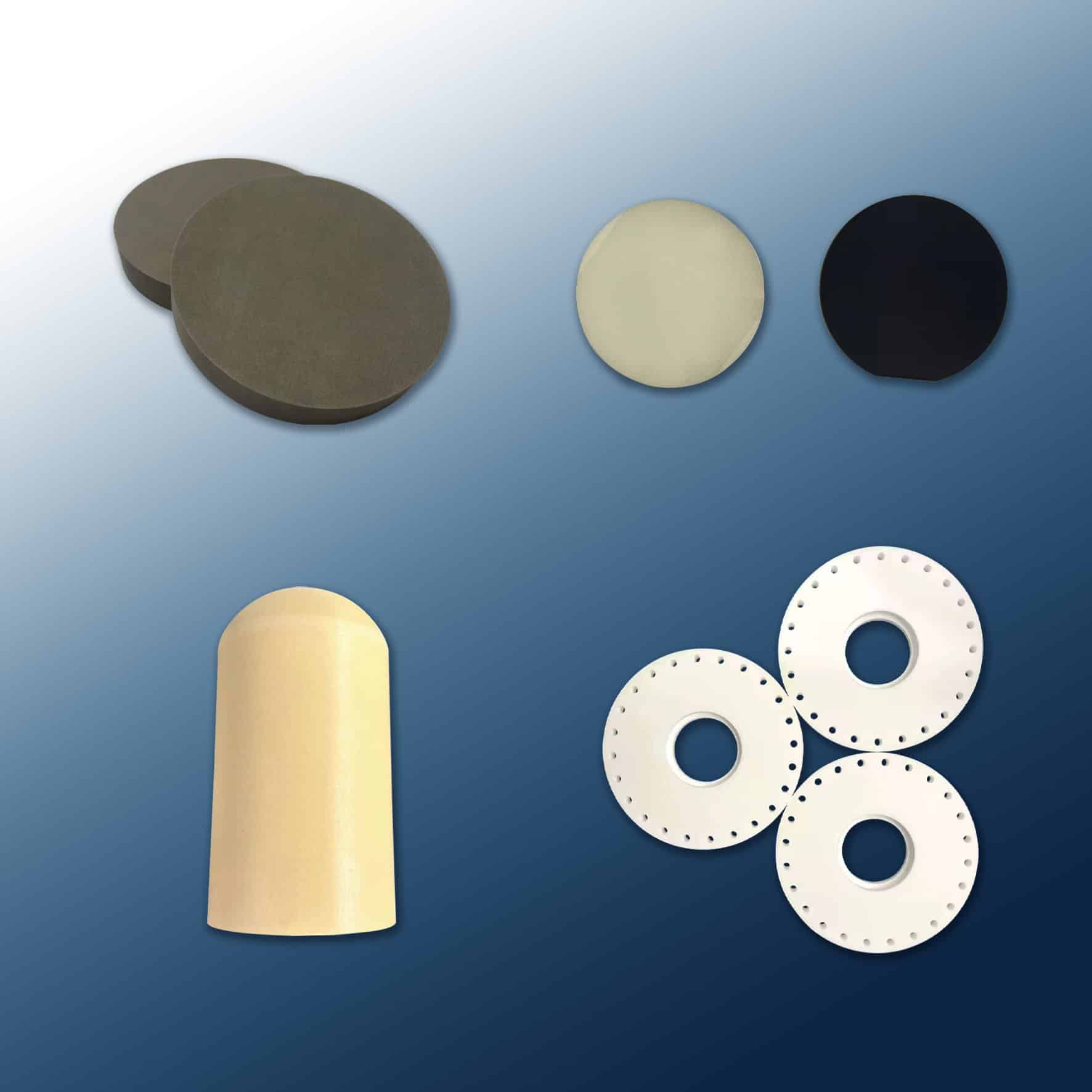

AdValue Technology can also provide materials below.

Dense Magnesium Oxide (MgO) ceramic is a highly durable, and thermally stable ceramic material composed primarily of magnesium oxide. Renowned for its high melting points, superior hardness, and strong resistance to chemical attack, MgO ceramic is ideal for a wide range of demanding industrial applications such as metallurgy, electronics, energy, and chemical processing. Common uses of MgO ceramics include high-temperature furnace components, crucibles, electrical insulation in heating elements, and protective coatings. Magnesium Oxide products offer outstanding thermal performance, withstanding temperatures up to 2200 °C (4000 °F).

AdValue Technology supplies high-purity Magnesium Oxide (MgO) products (>98% purity) in a variety of sizes and shapes. Please contact us to request a quote for custom MgO products.

At AdValue Technology, we offer high purity (>99.99%) single crystal (monocrystalline) Silicon Carbide (SiC) wafers. Compared to traditional silicon wafers, Silicon Carbide wafers deliver superior performance, excelling under higher temperatures, voltages, and frequencies, making them ideal for high-power and high-efficiency applications.

We supply 4H-SiC wafers in standard diameters of 2”, 3”, 4”, 6” and 8”. Custom specifications can be discussed upon request.

In addition to monocrystalline wafers, AdValue Technology also supplies polycrystalline silicon carbide products engineered for mechanical strength and thermal shock resistance. We provide both Sintered SiC (SSiC) and Reaction-Bonded SiC (RB-SiC) ceramics:

Featuring ~99% SiC, dense microstructure, exceptionally high mechanical strength, superior thermal conductivity, and excellent chemical resistance. SSiC is ideal for applications such as high-end kiln furniture, mechanical seals, pump components and space parts.

A composite of SiC and free silicon (Si), RB-SiC offers good strength and good chemical resistance, though lower than sintered SiC. Its thermal conductivity is also lower. Reaction-Bonded SiC serves as a cost-effective alternative for large kiln furniture (setter plates, beams, saggers, etc.) and cost-sensitive components.

AdValue Technology delivers high-quality silicon carbide products in a range of sizes and shapes. Please contact us to discuss your application requirements or request a quote for custom SiC products.

Silicon Nitride is an advanced technical ceramics known for handling extreme environments where metals or polymers would fail. The material exhibits a few unique advantages:

AdValue Technology supplies custom Silicon Nitride products, available in a wide range of dimensions and shapes. Our Silicon Nitride offerings include bearings, turbine components, industrial nozzles and valves, cutting tools, automotive components, etc. Please contact us to request a quote for custom Silicon Nitride products.

Zirconia Toughened Alumina (ZTA) is an advanced ceramic composite that combines the high hardness and wear resistance of alumina (Al₂O₃) with the excellent fracture toughness of zirconia (ZrO₂). By incorporating a controlled amount of zirconia into the alumina matrix, ZTA significantly improves mechanical properties such as strength, toughness, and resistance to crack propagation compared to pure alumina ceramics.

ZTA is widely used in demanding applications where traditional ceramics would fail under mechanical stress, such as in cutting tools, wear-resistant components, and armor systems. It offers an ideal balance between hardness, toughness, and chemical stability, making it a material of choice for both industrial and medical applications.

AdValue Technology supplies custom zirconia toughened alumina (ZTA) products in a wide range of dimensions and shapes. Please contact us to request a quote for custom ZTA products.

Titanium Boride (TiB₂) is a highly valued ceramic material known for its exceptional combination of hardness, high melting point, excellent thermal conductivity, and chemical stability. TiB₂ products are typically characterized by extreme hardness, outstanding wear and erosion resistance, and the ability to withstand high temperatures without significant degradation. Additionally, TiB₂ possesses excellent electrical conductivity for a ceramic material, enabling its use in specialized applications like cathodes for aluminum smelting and electrodes in electrochemical processes.

Titanium boride products are often used as wear-resistant components, armor materials, electrodes for aluminum smelting, aerospace and electronic components, and crucibles and containers for molten metals.

AdValue Technology can provide custom Titanium Boride products in a wide range of dimensions and shapes. Please contact us to request a quote for custom Titanium Boride products.

Sintered Yttrium Oxide (Y2O3) products are high-performance ceramic materials distinguished by their excellent heat resistance, exceptional thermal stability, great chemical inertness, low thermal expansion and superior optical properties. With a melting point exceeding 2400 ℃, Yttrium Oxide remains chemically stable even when exposed to highly active metals (such as Ti, Al, Hf, Nb, etc.) at elevated temperatures. Additionally, Yttrium Oxide exhibits high transparency in the infrared spectrum and strong resistance to laser-induced damage.

Due to these unique characteristics, sintered Yttrium Oxide products are widely used as crucibles and linings for high-temperature metal processing, components for crystal growth systems, parts for plasma processing equipment, and laser host materials and optical windows.

AdValue Technology can provide custom Yttrium Oxide products in a wide range of dimensions and shapes. Please contact us to request a quote for custom Yttrium Oxide (Y2O3) products.

AdValue Technology offers high-performance thin film-deposited ceramic substrates that combine the inherent durability of ceramics with the versatile functionality of thin films. These substrates are essential components in a wide array of advanced technologies, including microelectronics, optoelectronics, and sensor systems.

Utilizing ion sputtering and ion-assisted evaporation techniques, metal films (such as Cr/Ni/Au and Ti/Pt/Au) are deposited onto various ceramic materials, including Alumina (Al₂O₃), Aluminum Nitride (AlN), Zirconia (ZrO₂), Beryllium Oxide (BeO), Ferrite, and microwave substrates. Our capabilities include the fabrication of fine-line circuits, precise metallization, ceramic edge-side graphics, sidewall coatings, and double-sided graphical circuits.

For custom ceramic film products designed to meet your specific requirements, please contact us to request a quote.