No products in the cart.

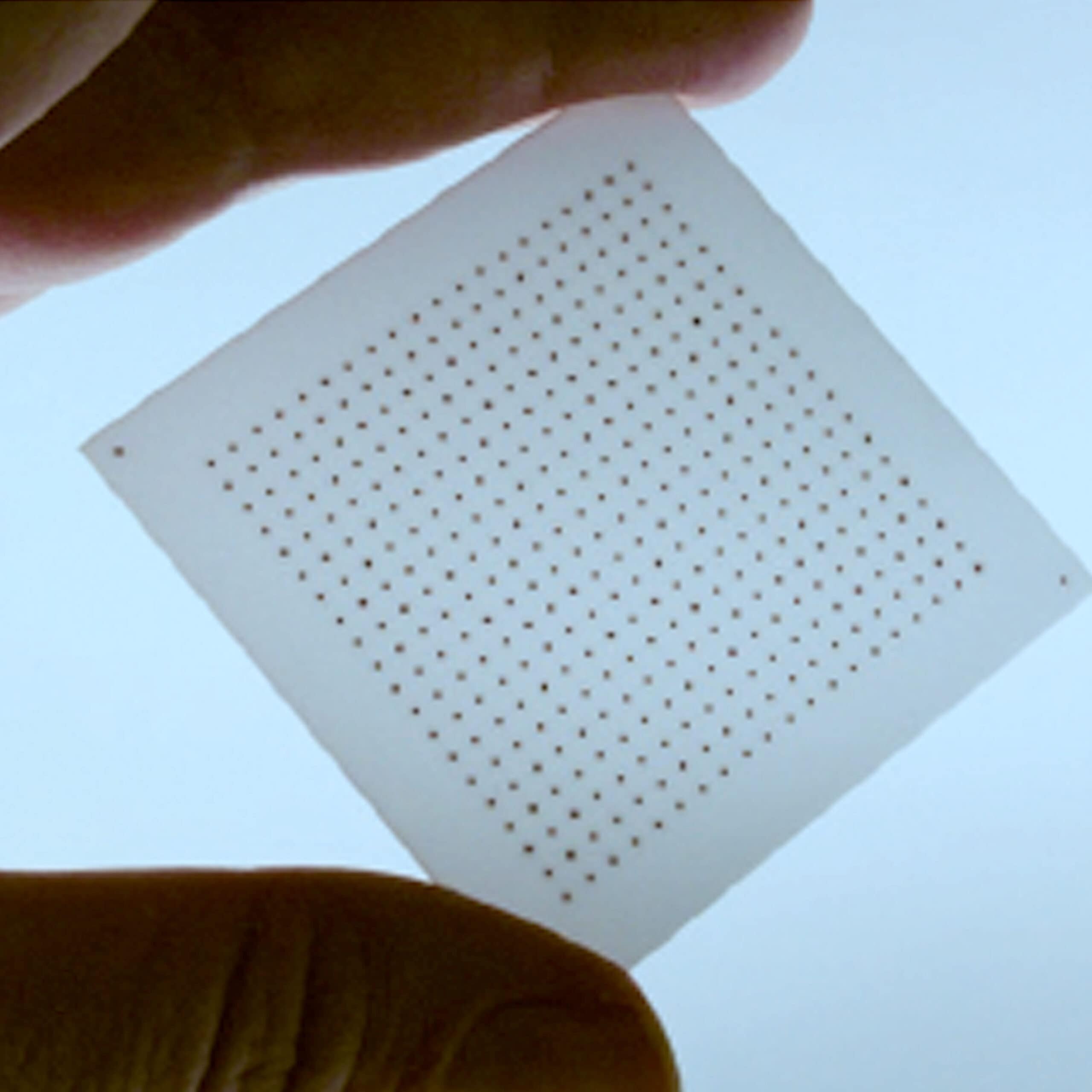

The via filling paste was developed for use on AlN and Al2O3 substrates.

The AgPt via filling paste FK1105 is specified for use on “AN180” AlN substrates, by CoorsTek (formerly ANCeram), and “Rubalit 7085” Al2O3 substrates, by CeramTec. Substrates with other surface qualities or from other manufactures may lead to variations in the results. The paste exhibits very little sinter shrinkage in order to fill the via as completely as possible. This helps to establish contact between buried and surface mentalizations of multi-layer ceramics.

The paste can be used for the metallization of vias in aluminum nitride and alumina. To fill the vias as fully as possible, stainless steel stencils should be used which are adapted to fit the thickness of the substrates. With regard to the via openings in the stencils, Fraunhofer IKTS recommends making the opening approx. One to five percent wider than the via diameters introduced in the ceramics.

| Characteristics | Unit | FK1105 |

|---|---|---|

| Material | -- | AgPt |

| Viscosity1 | Pa·S | TBD |

| Sheet resistance2,6 | mOhm/Sq | ≤10 |

| Solderability3,6 | % | TBD |

| Leaching resistance4,6 | Dips | TBD |

| Adhesion5(number offirings) | ||

| -Initial(1X)6 | N/4mm² | TBD |

| -Aged(1X)6 | TBD | |

| Fired film thickness | µm | 15±1 |

| Coverage7 | cm²/g | 63±5 |

–from Fraunhofer IKTS

All other specifications correspond to the general process conditions.