No products in the cart.

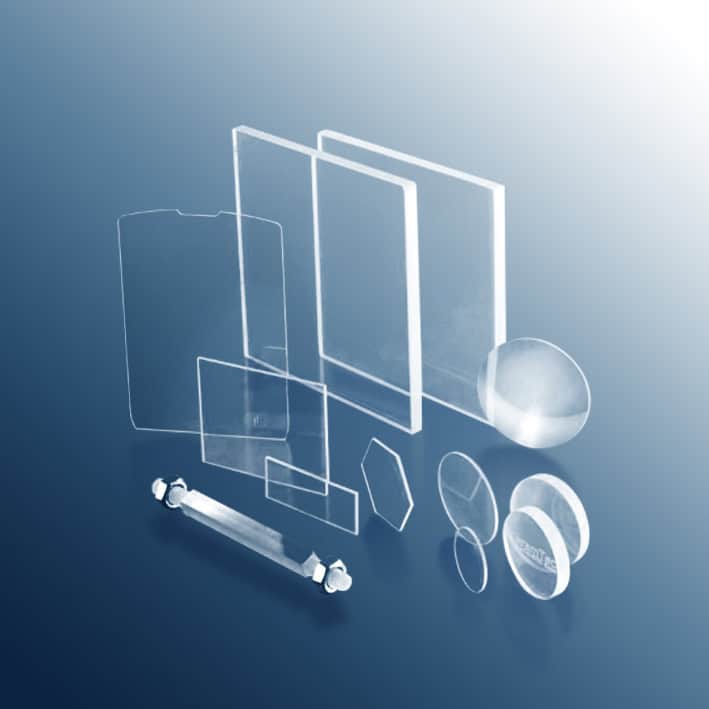

At AdValue Technology, we offer Perlucor® Transparent Ceramics (MgAl2O4) which combine outstanding optical clarity with exceptional hardness, thermal stability, and chemical resistance. Transparent Ceramics offer superior performance over glass and easier fabrication than sapphire. They are the perfect solution for high-demand applications requiring strength, transparency, and long-term durability.

Please contact us to discuss your application and request a quote of our Perlucor® Transparent Ceramics (MgAl2O4).

What are the key properties that make Perlucor® Transparent Ceramics ideal for high-performance applications?

Perlucor® Transparent Ceramics (MgAl₂O₄) are ideal for high-performance applications because they combine exceptional optical clarity with outstanding mechanical and thermal properties. Key properties include:

These combined properties make Perlucor® Transparent Ceramics a robust, versatile, and reliable solution for advanced applications requiring strength, transparency, and long-term performance.

How does the scratch resistance of Transparent Ceramics compare to other materials?

Perlucor® Transparent Ceramics have exceptional scratch resistance, making them far tougher than most natural and synthetic materials. On the Mohs hardness scale 8-9, they resist scratches and wear much better than conventional glass or quartz in many applications. This extreme hardness ensures that surfaces remain clear, durable, and free from abrasion over long-term use, making Transparent Ceramics ideal for protective windows, mobile device covers, optical components, and other high-wear environments.

What makes Transparent Ceramics more durable than conventional glass?

Perlucor® Transparent Ceramics are significantly more durable than conventional glass due to their superior mechanical strength, hardness, and chemical stability. With hardness several times greater than glass and superior resistance to scratches and wear, transparent spinel ceramics retain optical clarity and structural integrity in demanding environments. They also tolerate elevated temperatures and aggressive chemicals better than typical glasses. As a result, in many harsh industrial applications, Transparent Ceramics have service lives many times longer than conventional glass, making them ideal for applications that demand long-term reliability and durability under harsh conditions.

How high of a temperature can Transparent Ceramics withstand?

Perlucor® Transparent Ceramics can withstand temperatures of over 1,000°C (1,832°F), making them suitable for high-heat and demanding industrial applications. However, care must be taken with rapid temperature changes, as thermal shock may occur if the temperature difference between the inner and outer surfaces exceeds 180°C. Their combination of high-temperature resistance and thermal stability allows Transparent Ceramics to maintain mechanical strength, optical clarity, and chemical resistance even under extreme heat conditions.

What thermal limitations should be considered when using Transparent Ceramics?

When using Perlucor® Transparent Ceramics, the main thermal limitation to consider is thermal shock. While these ceramics can withstand temperatures over 1,000°C (1,832°F), rapid or uneven temperature changes can cause stress and cracking. Specifically:

By managing these thermal considerations, Transparent Ceramics can maintain their strength, optical clarity, and durability even in demanding high-temperature applications.

How resistant are Transparent Ceramics to acids, alkalis, and other chemicals?

Perlucor® Transparent Ceramics exhibit excellent chemical resistance, making them highly durable in harsh environments. They are stable against a wide range of acids and alkalis across various concentrations, temperatures, and exposure times. This resistance ensures that the material maintains its mechanical strength, optical clarity, and surface integrity even under prolonged chemical exposure. The main exception is prolonged contact with hydrofluoric acid, which can damage the ceramic. Overall, this chemical stability makes Transparent Ceramics ideal for industrial, medical, and laboratory applications where exposure to aggressive chemicals is common.

What optical properties make Transparent Ceramics suitable for visible and IR applications?

Perlucor® Transparent Ceramics are highly suitable for visible and infrared (IR) applications due to their exceptional optical properties:

These properties make Transparent Ceramics ideal for optical windows, sensor covers, protective screens, and imaging systems that require reliable, high-performance transmission in both visible and IR ranges.

How does the absence of birefringence benefit optical performance?

The absence of birefringence in Perlucor® Transparent Ceramics ensures that light passes through the material without splitting into two separate rays, which can otherwise cause distortion, double images, or changes in polarization. This provides several benefits for optical performance:

Overall, the lack of birefringence ensures high-quality, distortion-free optics, making Transparent Ceramics ideal for demanding optical and imaging applications.

Can Transparent Ceramics be used in electrical or RF applications?

Yes, Perlucor® Transparent Ceramics are suitable for electrical and RF (radio frequency) applications because they combine excellent electrical insulation with stable dielectric properties and very low dielectric loss.These characteristics allow the material to:

These properties make Transparent Ceramics ideal for applications such as sensor covers, optical windows in RF systems, high temperature electronics, high-frequency devices, and advanced communication systems where both optical clarity and electrical performance are required.

What types of applications are Transparent Ceramics commonly used for?

Perlucor® Transparent Ceramics are used in a wide range of high-performance applications where strength, transparency, and durability are critical. Common applications include:

These applications leverage Transparent Ceramics’ combination of mechanical strength, optical clarity, chemical resistance, and thermal stability for reliable long-term performance.

How are Transparent Ceramics used in ballistic protection or safety windows?

In ballistic protection and safety windows, Perlucor® Transparent Ceramics are used as a hard, impact-resistant layer that can absorb and dissipate energy from projectiles, blasts, or mechanical impacts. Key aspects include:

These properties make Transparent Ceramics ideal for military armor, law enforcement shields, industrial safety windows, and blast-resistant observation ports where both visibility and protection are critical.

Can Transparent Ceramics be used for mobile device components like phone or camera covers?

Yes, Perlucor® Transparent Ceramics are ideal for mobile device components such as phone screens, camera covers, and head-up displays. Their extreme hardness and scratch resistance protect delicate surfaces from everyday wear and impact. Additionally, they offer high optical clarity, ensuring that displays and camera lenses deliver sharp, accurate images. Their thin, durable form allows integration into compact devices, while chemical and thermal stability ensures long-term performance, even with frequent handling, exposure to sunlight, or temperature variations. This combination of protection, clarity, and durability makes Transparent Ceramics a premium material for modern mobile electronics.

Are Transparent Ceramics suitable for scanner systems and sensor covers?

Yes, Perlucor® Transparent Ceramics are highly suitable for scanner systems and sensor covers due to their combination of optical clarity, mechanical strength, and chemical resistance. Key benefits include:

These properties make Transparent Ceramics an excellent choice for document scanners, imaging systems, environmental sensors, and other precision optical devices that require both protection and high-performance light transmission.

How are Transparent Ceramics applied in watches or other precision instruments?

Perlucor® Transparent Ceramics are used in watches and precision instruments for components that demand durability, scratch resistance, and optical clarity. Typical applications include:

Their hardness, optical performance, and chemical resistance ensure that watches and instruments maintain functionality and appearance over time, even under daily wear, environmental exposure, or repeated handling.

Can Transparent Ceramics be used in architectural or lighting applications?

Yes, Perlucor® Transparent Ceramics are well suited for architectural and lighting applications due to their combination of strength, durability, and optical clarity. Common uses include:

These properties allow Transparent Ceramics to deliver durable, visually appealing, and high-performance solutions for both functional and aesthetic architectural or lighting projects.

What standard sizes and dimensions are available for Transparent Ceramics?

Perlucor® Transparent Ceramics are available in a variety of standard plate sizes to suit different applications. Typical dimensions include:

These sizes can accommodate various geometries or disc formats within the specified measurements. Additionally, multiple plates can be laminated or bonded to carrier glass to achieve larger custom dimensions, providing flexibility for both standard and specialized applications.

What dimensional tolerances can be achieved for plates and discs?

Perlucor® Transparent Ceramics can be manufactured with precise dimensional tolerances to meet demanding application requirements:

These tight tolerances ensure that plates and discs fit accurately in assemblies, maintain optical performance, and are suitable for high-precision applications such as optics, sensors, mobile devices, and protective windows.

Are custom dimensions or disc formats available for Transparent Ceramics?

Yes, Perlucor® Transparent Ceramics can be fabricated in custom dimensions and disc formats to meet specific application requirements. Within the standard size ranges, AdValue Technology can produce unique cutouts, and contours tailored for optical components, protective windows, sensors, or other specialized devices. Custom fabrication ensures that the ceramics fit precisely, maintain optical clarity, and meet mechanical and thermal performance needs for demanding applications.

Can Transparent Ceramics be laminated onto carrier glass or bonded to multiple plates?

Yes, Perlucor® Transparent Ceramics can be laminated onto carrier glass or bonded to multiple plates to create larger or more complex assemblies. This allows designers to:

This flexibility makes Transparent Ceramics suitable for applications where large, durable, and optically precise surfaces are required.

How do Transparent Ceramics compare to sapphire and conventional glass in terms of performance and fabrication?

Perlucor® Transparent Ceramics offer a unique balance of performance and manufacturability compared to sapphire and conventional glass:

Overall, Transparent Ceramics combine high durability, optical performance, and thermal/chemical resistance with greater ease of fabrication, offering a practical and high-performance alternative to both conventional glass and sapphire for advanced applications.