No products in the cart.

At AdValue Technology, we offer advanced laser machining services tailored to meet the most demanding industrial requirements. With state-of-the-art laser technology and precision engineering expertise, we provide high-quality results across a wide range of materials and applications.

Our versatile laser marking services can handle virtually any material, from metals and plastics to glasses, ceramics and composites. Whether you need high-contrast logos, serial numbers, barcodes, or traceability marks, we deliver permanent, clean, and precise results without damaging the underlying material.

We provide fine laser scribing for brittle and hard materials, ensuring minimal micro-cracks and excellent edge quality. Ideal for pre-cutting, scoring, or controlled-depth lines for:

Our laser drilling solutions offer high-aspect-ratio, burr-free holes with exceptional precision and repeatability, particularly for materials that are difficult to machine using traditional methods.

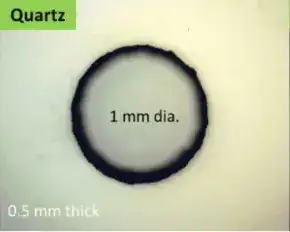

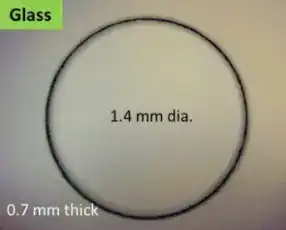

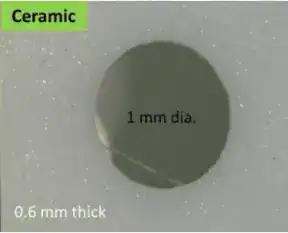

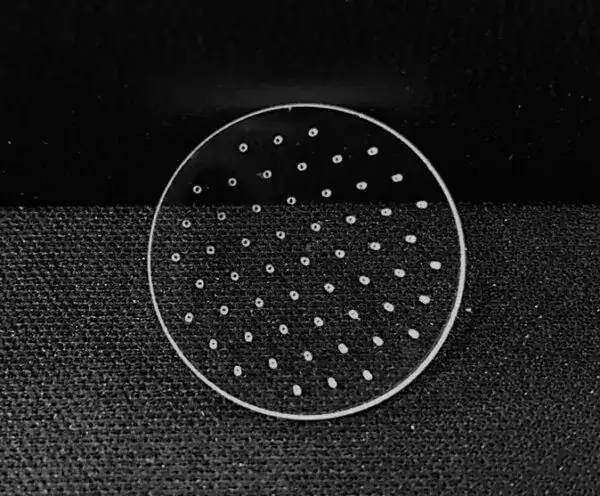

Figure 1. Optical microscopy images of millimeter diameter holes drilled by ultrashort pulse lasers on sapphire, fused quartz, borosilicate glass, and Al2O3 ceramic substrates.

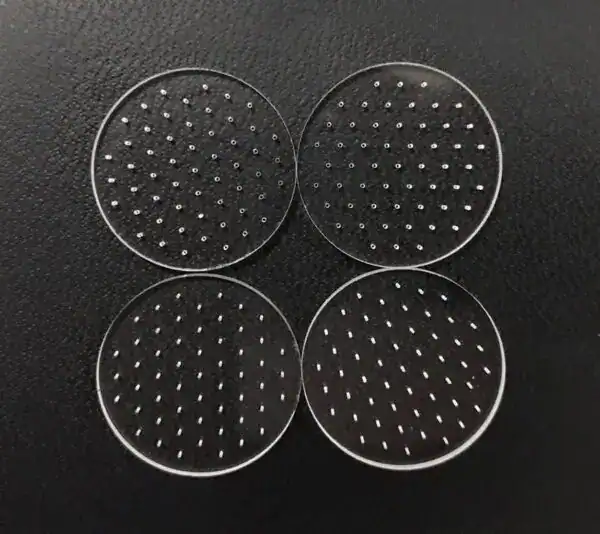

Figure 2. Fused quartz discs OD20mm*T1.5mm with 55 Dia0.25mm holes, tolerance <20µm, chip <100µm or <20µm

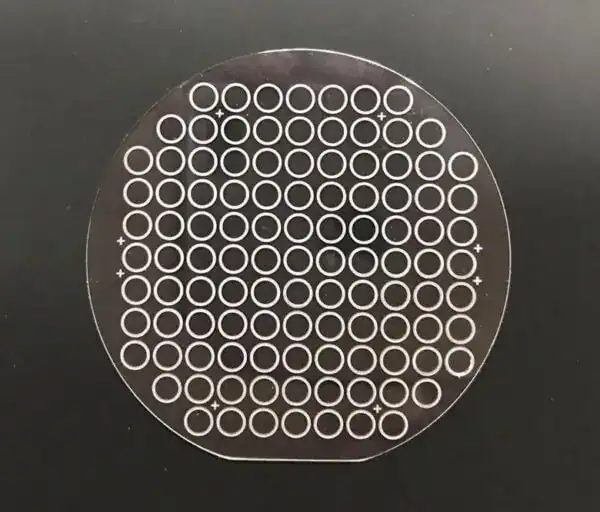

Figure 3. Sapphire wafer with 0.3mm thickness. 109 round Ø2.9mm blind slots with depth 0.15mm, chip < 20µm.

We specialize in clean, chip-free cutting of brittle and transparent materials where traditional cutting fails.

Looking for high-quality industrial laser machining? Contact us today for a consultation or a custom quote. We’ll work closely with you to develop the best laser solution for your application.