No products in the cart.

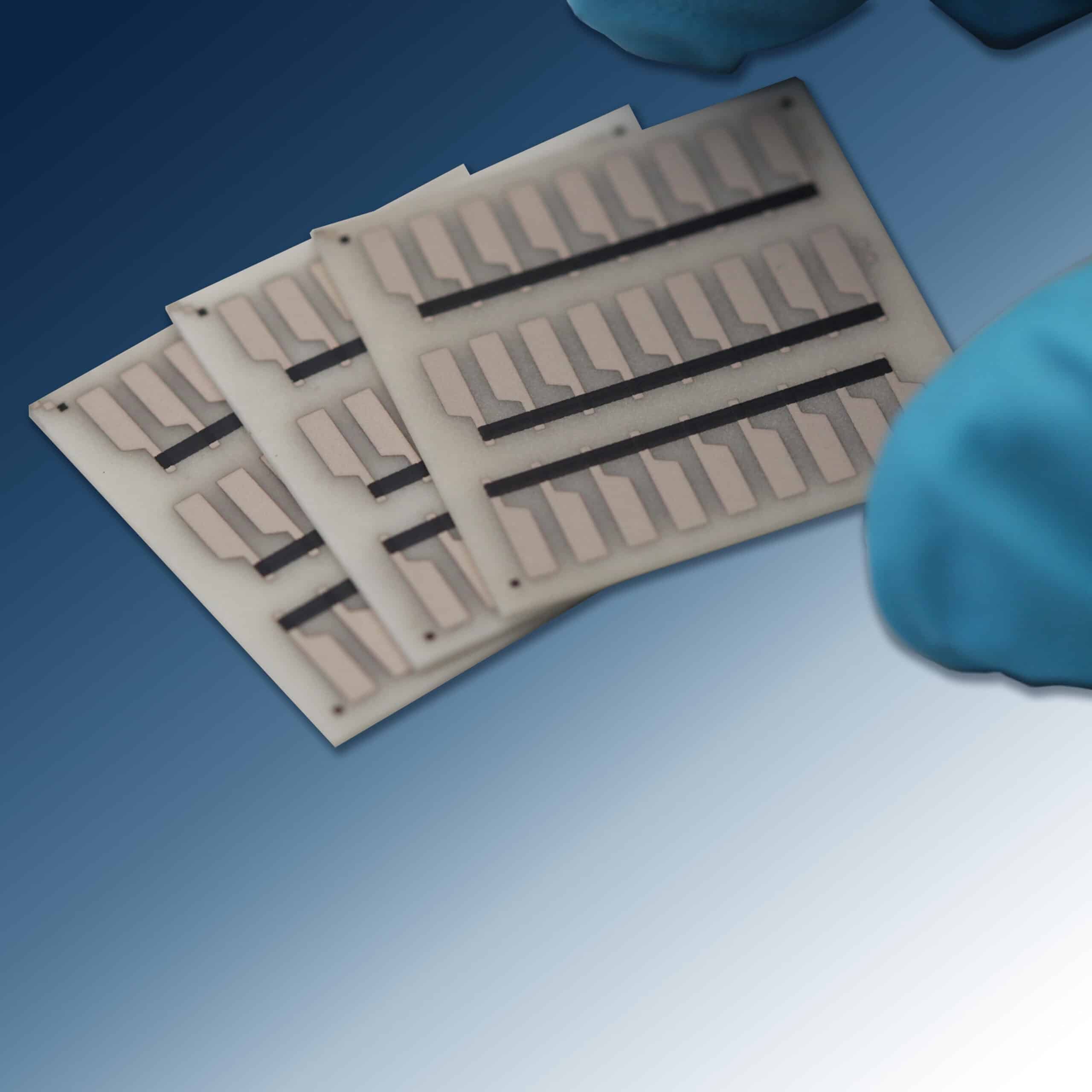

FK9600, FK9900M-100 and FK9900M-200 resistor paste systems were specially developed for use on AlN substrates, enabling the production of high-precision thick-film resistors suitable for power electronics applications.

The RuO2-based FK9600 resistor paste system, with sheet resistance values of 6 to 6,000 Ohm/Sq, is compatible with the conductor pastes FK1205, FK1916 and FK1953, as well as with the encapsulation paste FK4027. Other pastes can be used as conductor paste, but this may result in differing sheet resistance values or temperature coefficients. The pastes of the FK9600 paste system in the table below can be mixed with each other as needed. We do not recommend mixing with the resistor pastes of the FK9900M series.

The AgPd-based resistor paste systems FK9900M-100 and FK9900M-200, with a temperature coefficient of resistance lower than 100 ppm/K, or lower than 200 ppm/K, respectively, are compatible with the conductor pastes FK1205, FK1916 and FK1953, as well as the encapsulation paste FK4027. Other pastes can be used as conductor paste, but this may result in differing sheet resistance values or temperature coefficients. The pastes listed below may be mixed with each other. It is possible to combine these pastes with those of the FK9600 series without an additional contact film. To do this, it is required to fire the pate film before printing the next one. We do not recommend mixing the FK9900M with pastes of the RuO2-based FK9600 paste series.

| Characteristics | Unit | FK9606 | FK9611 | FK9615 | FK9621 | FK9631 | FK9632 | FK9636 |

|---|---|---|---|---|---|---|---|---|

| Viscosity1 | Pa·S | 220±30 | 220±30 | 220±30 | 220±30 | 220±30 | 220±30 | 220±30 |

| Sheet resistance2,3 | Ohm/Sq | 6 | 10 | 50 | 100 | 1000 | 2000 | 6000 |

| Shipping specification | % | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 |

| Hot TCR2,4 | ppm/K | 0±200 | 0±100 | 0±100 | 0±100 | 0±100 | 0±200 | 0±300 |

| Cold TCR2,4 | ppm/K | 0±200 | 0±100 | 0±100 | 0±100 | 0±100 | 0±300 | 0±300 |

| Dried film thickness | µm | 22±2 | 22±2 | 22±2 | 22±2 | 22±2 | 22±2 | 22±2 |

| Coverage5 | cm²/g | 105±5 | 105±5 | 105±5 | 110±5 | 110±5 | 110±5 | 110±5 |

–from Fraunhofer IKTS

All other specifications correspond to the general process conditions.

| Parameter | Unit | FK9900M-100 | FK9900M-200 | ||||

|---|---|---|---|---|---|---|---|

| FK9921M | FK9931M | FK9941M | FK9921M | FK9931M | FK9941M | ||

| Viscosity 1 | Pa·S | TBD | TBD | TBD | TBD | TBD | TBD |

| Sheet resistance 2,3 | mOhm/Sq | 100 | 1000 | 10000 | 100 | 1000 | 10000 |

| Shipping specification | % | ±20 | ±20 | ±20 | ±20 | ±20 | ±20 |

| Hot TCR 2,4 | ppm/K | 0±100 | 0±100 | 0±100 | 0±200 | 0±200 | 0±200 |

| Cold TCR 2,4 | ppm/K | 0±100 | 0±100 | 0±100 | 0±200 | 0±200 | 0±200 |

| Dried film thickness | µm | 21±2 | 21±2 | 21±2 | 21±2 | 21±2 | 21±2 |

| Coverage 5 | cm²/g | 80±5 | 95±5 | 100±5 | 80±5 | 95±5 | 100±5 |

–from Fraunhofer IKTS

All other specifications correspond to the general process conditions.