No products in the cart.

Our ceramic membranes and carriers are developed for the optimal separation of a wide range of fluids and gases. Application areas include:

Compared to polymers, ceramic membranes offer a narrow pore size distribution exactly matching the components to be separated. They also provide better resistance against aggressive chemicals, high temperatures, a high and constant flux and a long service life.

Ceramic carriers are an ideal base for membranes and micro-filtration applications in the chemical, pharmaceutical and food industry as well as in water and waste water processing.

The polymer-free all-ceramic sealing of our membrane tube assemblies leads to several clear advantages:

SUBSTRATE CHARACTERISTICS | |||||||

|---|---|---|---|---|---|---|---|

| Substrate material | α-aluminum oxide | ||||||

| Operating mode | crossflow | ||||||

| Configuration | Multiple options | ||||||

| Length | max. 1200 mm, standard lengths are 250, 600 and 1200mm | ||||||

| Structure | Symmetric | Asymmetric | |||||

| Mean pore diameter | 2 µm | 1 µm | 0.6 µm | 0.2 µm | 0.1 µm | 40 nm | 20 nm |

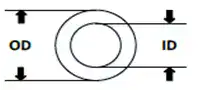

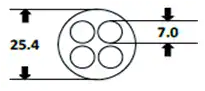

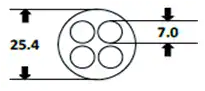

| Configuration | Design | No. of Channels | OD/ID (mm) | Length (mm) | Surface (m2) | Drawing |

|---|---|---|---|---|---|---|

| Single Bore |  | 1 | <18.0/>1.0 | ≤ 1200 | 0.003~0.06 |  |

| 4-tube system |  | 4 | 25.4/7.0 | ≤ 1200 | ~0.11 |  |

| Multi-bore |  | 4 | 25.4/7.0 | ≤ 1200 | ~0.11 |  |

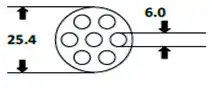

| Multi-bore |  | 7 | 25.4/6.0 | ≤ 1200 | ~0.16 |  |

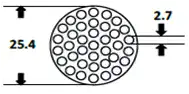

| Multi-bore |  | 37 | 25.4/2.7 | ≤ 1200 | ~0.38 |  |

| Hollow fiber | 1” module with hollow fibers | 19 | Fiber 4.3/2.8 | 166 | ~0.03 |  |

| Hollow fiber | 4” module with hollow fibers | 220 | Fiber 4.3/2.8 | 360 | ~0.7 | |

| Hollow fiber | 8” module with hollow fibers | 1300 | Fiber 4.3/2.8 | 360 | ~4.1 |

Want to know more about the ceramic membranes? Email us using our Contact Us Form or call us at 520-514-1100 for further discussion.